Decorative perforated metal is a remarkable material that blends functionality with aesthetic appeal. In this comprehensive guide, we will explore everything you need to know about decorative perforated metal, from its origins to its contemporary applications across various industries.

What is Decorative Perforated Metal?

Decorative perforated metal refers to sheets of metal that have been perforated with holes to create unique patterns and designs. This versatile material can be made from various metals, including aluminum, steel, and stainless steel, allowing for a range of finishes and applications.

The Process of Creating Perforated Metal

The creation of decorative perforated metal involves several steps:

- Material Selection: Choose the type of metal based on the desired properties and use case.

- Design Creation: Create a design that specifies the size, shape, and distribution of holes.

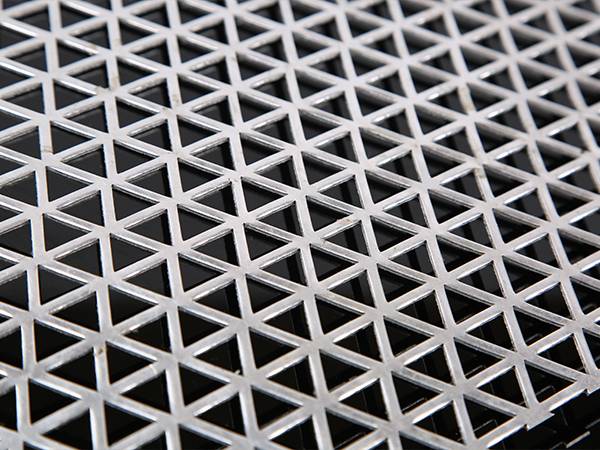

- Perforation: Use specialized machines to punch holes into the metal sheet.

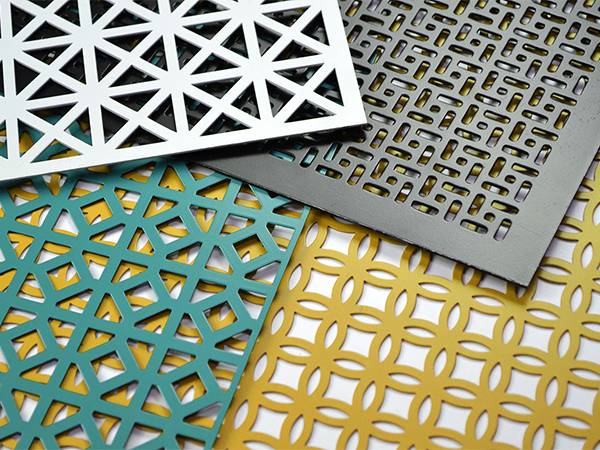

- Finishing: Apply any desired surface treatments, such as powder coating or anodizing, to enhance durability and aesthetics.

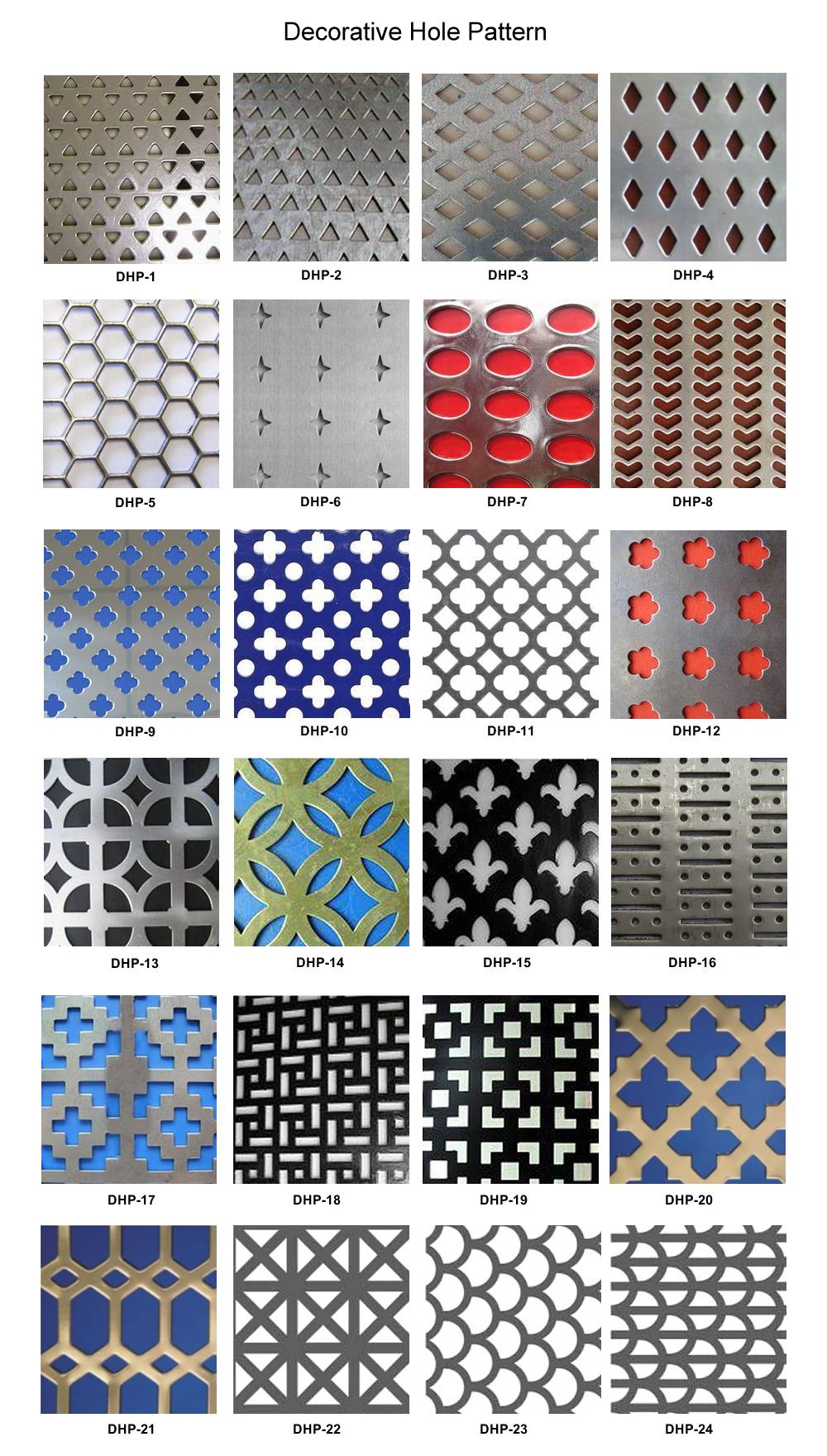

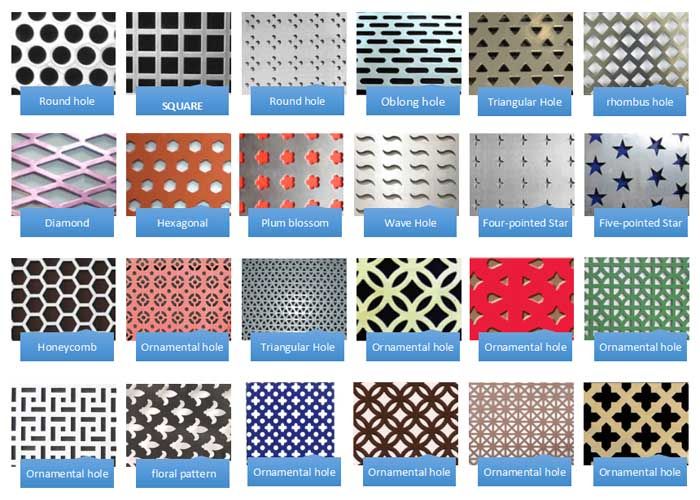

Types of Decorative Perforated Metal

Decorative perforated metal comes in various patterns and shapes, each serving different purposes. Below are some popular types:

1. Round Hole Perforations

Round holes are the most common type of perforation and can be arranged in various spacing configurations.

2. Square Hole Perforations

Square holes offer a modern aesthetic and are often used in architectural applications.

3. Custom Shapes

For unique projects, custom shapes can be designed to meet specific project requirements or artistic visions.

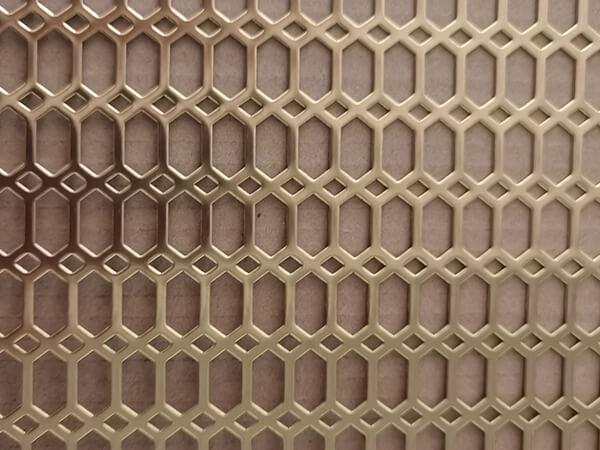

4. Decorative Patterns

Patterns can range from geometric shapes to organic designs, providing artistic flair to any project.

Common Applications of Decorative Perforated Metal

Decorative perforated metal is used in various industries, including:

1. Architecture and Interior Design

In architecture, perforated metal can be used for facades, screening, and railings, providing both beauty and privacy.

2. Furniture Design

Many furniture designers incorporate perforated metal in chairs, tables, and shelving for a contemporary look.

3. Industrial Applications

Perforated metal is utilized in industrial settings for ventilation, filters, and noise reduction panels.

4. Art Installations

Artists use perforated metal to create stunning sculptures and installations that play with light and shadow.

Benefits of Using Decorative Perforated Metal

Choosing decorative perforated metal comes with several advantages:

1. Aesthetic Flexibility

With various patterns and finishes available, decorative perforated metal can fit any design style, from traditional to modern.

2. Durability and Longevity

Metal is inherently durable, making it an excellent choice for both indoor and outdoor applications.

3. Light and Ventilation Management

Perforated metal allows for optimal airflow while maintaining privacy or aesthetic design needs.

4. Sustainability

Many perforated metals are recyclable, contributing to sustainability efforts in design and construction.

Considerations When Choosing Decorative Perforated Metal

Before choosing decorative perforated metal for your project, here are some considerations:

1. Material Type

Consider the environment in which the metal will be used. For exterior applications, rust-resistant options like aluminum or stainless steel may be best.

2. Hole Configuration

The size, shape, and pattern of the perforations can affect both functionality and aesthetics. Choose based on the intended use.

3. Finish Options

Different finishes can enhance the metal’s appearance and durability. Popular options include powder coating, anodizing, and painting.

4. Cost Considerations

Budget is always a factor. Compare different materials and options to find a balance between quality and cost.

Comparison Table of Popular Perforated Metals

| Material | Durability | Cost | Common Uses |

|---|---|---|---|

| Aluminum | High | Medium | Outdoor structures, art installations |

| Stainless Steel | Very High | High | Architectural facades, industrial applications |

| Carbon Steel | Medium | Low | Indoor applications, furniture |

Installation Tips for Decorative Perforated Metal

Here are some tips for installing decorative perforated metal successfully:

1. Prepare the Surface

Ensure the surface where the metal will be installed is clean and free from debris.

2. Use Appropriate Fasteners

Select fasteners that are compatible with the type of metal you are using to prevent corrosion and ensure stability.

3. Plan for Ventilation

If the perforated metal is being used for screen applications, consider airflow needs to maintain functionality.

4. Follow Manufacturer Guidelines

Always adhere to the manufacturer’s recommendations for installation to ensure longevity and safety.

Pros and Cons of Decorative Perforated Metal

Like any material, decorative perforated metal has its advantages and disadvantages:

Pros

- Versatile design options

- Durable and long-lasting

- Enhances light distribution while maintaining privacy

- Environmentally friendly options available

Cons

- High-quality options can be costly

- Some materials may require maintenance to prevent rust

- Installation can be complex depending on the application

FAQs about Decorative Perforated Metal

What is the difference between perforated and expanded metal?

Perforated metal has holes punched into it in specific patterns, while expanded metal is created by cutting and stretching a sheet of metal to form diamond-shaped openings.

Can decorative perforated metal be painted?

Yes, perforated metal can be painted or coated to enhance its appearance and protect it from corrosion. Powder coating is a popular choice.

Is decorative perforated metal suitable for outdoor use?

Absolutely! When using a rust-resistant metal like aluminum or stainless steel, decorative perforated metal is perfect for outdoor applications.

How do I clean decorative perforated metal?

Cleaning can be done with mild soap and water. Avoid abrasive cleaners that can scratch the surface.

Conclusion

Decorative perforated metal is an exceptional material that combines beauty, durability, and functionality. Its versatility allows it to be used in a wide variety of applications, from architecture to art installations. By understanding its types, benefits, and installation considerations, you can make informed decisions for your next project. I personally have witnessed the transformative power of decorative perforated metal in both my home and professional projects, and I hope this guide inspires you to explore its possibilities!