When it comes to home and business decor, finding the right balance between aesthetics and functionality can be challenging. As someone who has worked in interior design for several years, I can attest to the transformative power of laser cut panels decorative. These intricate designs serve not only as stunning visual elements but also as versatile solutions for a variety of applications.

What Are Laser Cut Panels?

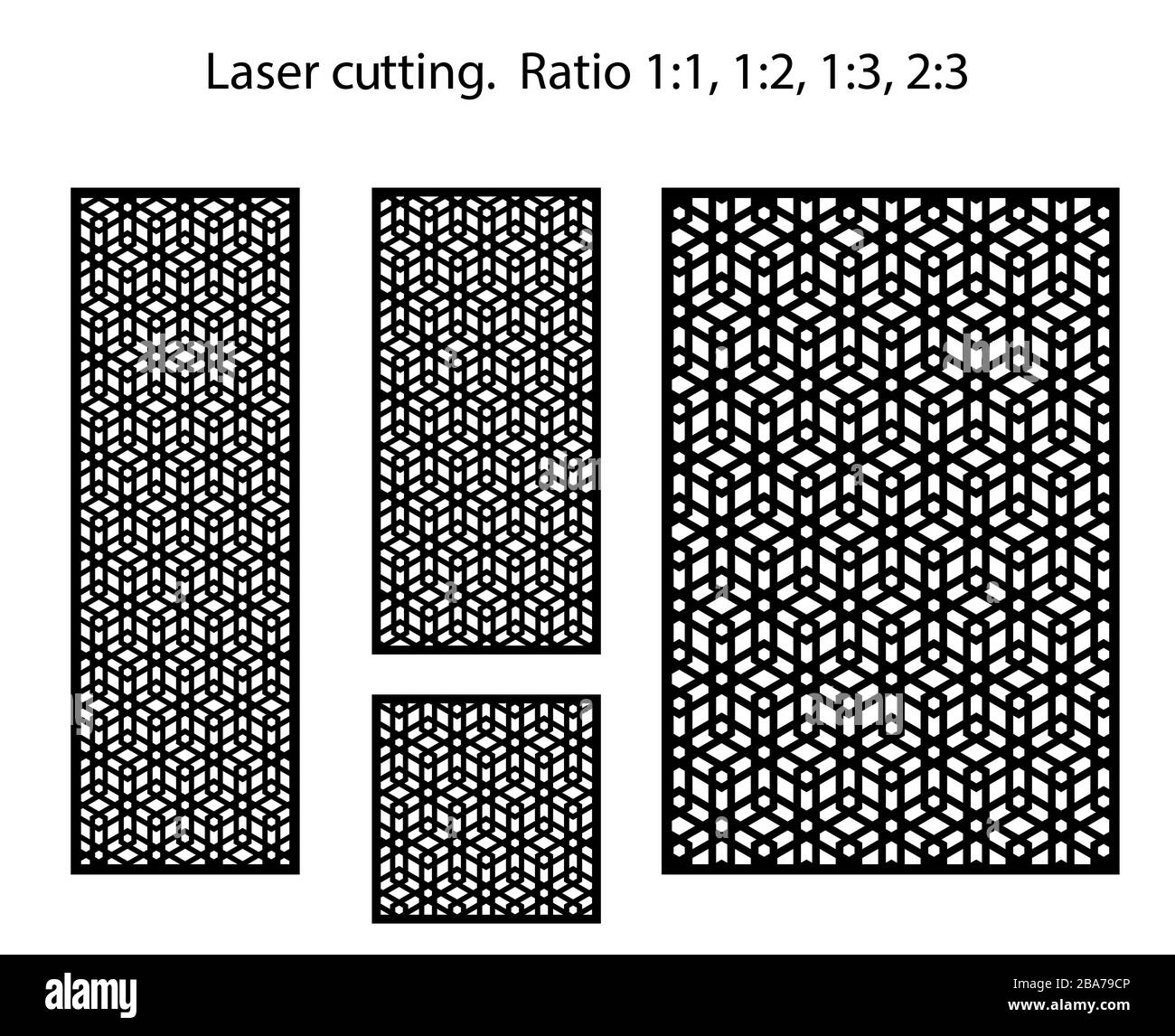

Laser cut panels are decorative elements that are crafted using laser cutting technology. They can be made from a variety of materials, including wood, metal, acrylic, and more. The precision of laser cutting allows for complex designs to be produced with high accuracy, resulting in stunning panels that can elevate any space.

The Technology Behind Laser Cutting

In the realm of modern manufacturing and design, laser cutting has revolutionized how we create intricate patterns and shapes. This technology uses a high-powered laser to cut through materials with incredible precision. The benefits of this method include:

- High precision and accuracy

- Ability to create complex designs

- Efficient material usage

- Quick production times

Why Choose Laser Cut Panels for Decoration?

There are several compelling reasons to choose laser cut panels for your decorative needs. Here’s a closer look at some of the key benefits:

1. Aesthetically Pleasing

Laser cut panels come in countless designs, from geometric patterns to organic forms. Whether you want a modern look or something more traditional, there’s likely a panel to suit your taste.

2. Versatility

These panels can be used in various applications, including:

- Wall art

- Room dividers

- Furniture accent pieces

- Lighting fixtures

- Outdoor decor

3. Durability

Laser cut panels are crafted from durable materials that can withstand wear and tear, making them a long-lasting choice for decor.

4. Customization

Many companies offer custom designs, allowing you to create a unique piece that reflects your personal style.

Types of Laser Cut Panels

Laser cut panels can be categorized based on their material and application. Here’s an overview:

1. Material Types

| Material | Characteristics | Best Use Cases |

|---|---|---|

| Wood | Warm, natural look; can be stained or painted | Indoor decor, furniture accents |

| Metal | Modern, industrial feel; available in various finishes | Outdoor decor, gate designs, wall art |

| Acrylic | Lightweight and colorful; can be backlit | Lighting fixtures, modern art pieces |

| Cardboard | Eco-friendly, lightweight; suitable for temporary displays | Event decorations, exhibitions |

2. Design Styles

Laser cut panels also embody various design styles, which can be categorized as follows:

- Geometric Patterns: Clean lines and shapes suitable for modern interiors.

- Nature-Inspired: Leaf motifs and organic shapes for a calming ambiance.

- Artistic Designs: Unique, hand-crafted looks that add character.

- Custom Logos: Personalized designs for branding and commercial use.

Applications of Laser Cut Panels

From home decor to commercial settings, laser cut panels offer a wealth of applications. Here’s how you can utilize them:

1. Home Decor

Transform your living space with laser cut panels in various forms:

- Wall Art: Create a focal point in any room.

- Room Dividers: Use them to separate spaces without sacrificing light.

- Furniture Accents: Incorporate them into tables or cabinets for added flair.

2. Commercial Use

Businesses can also benefit from laser cut panels:

- Branding: Use custom logos in the design.

- Signage: Create unique signs that stand out.

- Interior Design: Enhance the ambiance of cafes, restaurants, and retail stores.

3. Outdoor Applications

Laser cut panels can also beautify outdoor spaces:

- Garden Screens: Create privacy while adding artistic elements.

- Gates: Incorporate them in gates for a stylish entry.

- Decorative Fences: Add flair to your property lines.

Pros and Cons of Laser Cut Panels

Pros

- Highly customizable to suit individual tastes.

- Wide range of materials and designs available.

- Durable and long-lasting with appropriate care.

- Can be used in both indoor and outdoor applications.

Cons

- Potentially high initial investment, depending on design complexity.

- Some materials may require special care to maintain appearance.

- Installation may be challenging for very large panels.

How to Choose the Right Laser Cut Panel

Selecting the perfect laser cut panel can be overwhelming given the multitude of options available. Here are some tips to guide your decision:

1. Define Your Purpose

Think about where and how you intend to use the panel. Is it for privacy, decoration, or branding? Your answer will help narrow down your choices.

2. Consider the Material

Choose a material that fits your style and complements your space. For instance, metal panels work well for industrial spaces, while wood might suit a more rustic setting.

3. Design and Aesthetic

Make sure the design aligns with your existing decor. Consider hiring a designer if you’re looking for a custom piece.

4. Budgeting

Have a clear budget in mind. Remember that while some panels can be affordable, custom options may carry a higher price tag.

Installation Tips for Laser Cut Panels

Once you’ve chosen the perfect panel, proper installation is crucial for achieving the best results. Here are some tips based on my personal experience:

1. Prepare Your Space

Ensure the area where the panel will be installed is clean and free of obstacles.

2. Gather Tools and Materials

You may need tools such as a level, measuring tape, and appropriate fasteners based on your panel and wall type.

3. Seek Professional Help if Necessary

If you’re unsure about installing the panel yourself, consider hiring a professional to ensure it’s done correctly.

Maintenance of Laser Cut Panels

To keep your laser cut panels looking fresh and beautiful, here are some maintenance tips:

1. Regular Cleaning

Dust the panels regularly using a soft cloth or a duster. Avoid harsh chemicals, especially for wood and metal panels.

2. Protect from Moisture

If your panels are outdoors, ensure they are treated to withstand moisture and changing weather conditions.

3. Touch-Up Paint or Finish

For wooden panels, once in a while, apply a finish to protect and enhance their look.

Cost of Laser Cut Panels

The price of laser cut panels can vary widely based on several factors, including:

1. Material Choice

Wood is generally more affordable, while metal and custom designs can cost significantly more.

2. Size of the Panel

Larger panels will naturally be more expensive due to increased material usage and labor.

3. Complexity of Design

Intricate designs may require more time to produce, thus increasing the overall cost.

Conclusion

In conclusion, laser cut panels decorative are an innovative and stylish solution to elevate both residential and commercial spaces. With their versatility, durability, and aesthetic appeal, these panels can cater to various design needs. Whether you’re seeking to make a bold statement or just add a subtle touch of elegance, laser cut panels can transform your environment effortlessly.

FAQs

1. What materials are best for laser cut panels?

Popular materials include wood for a rustic feel, metal for industrial charm, and acrylic for colorful, modern aesthetics.

2. Can I customize laser cut panels?

Yes! Many companies offer custom designs, allowing you to create a unique piece tailored to your style and needs.

3. Are laser cut panels suitable for outdoor use?

Absolutely! Many materials used for laser cut panels are weather-resistant and suitable for outdoor applications.

4. How do I maintain my laser cut panels?

Regularly dust them with a soft cloth, protect them from moisture, and apply a finish as needed to maintain their appearance.

5. What’s the average cost of laser cut panels?

The cost can range from $50 to several hundred dollars, depending on material, size, and design complexity.